- Process Workflow:-The paper shall be transmitted from mill stand to single-roller for pre-heating and humidity adjusting, to single facer to further

heating, fluting and gluing to be single-corrugated sheet, then to over bridge through pulling for orderly transmitting, to multi-roller pre-heater for again heating, to pasting machine for gluing, to double facer for bottom paper combination to be corrugated sheet, to slitting machine and NC cut off for required sheet and lastly to stacking machine for stacking and outputting. - Available width 1400mm-length 2200mm and can be customized.

- Production speed-60m/min to 220m/min.

- Fluting type-A flute, B flute, C flute, E flute.

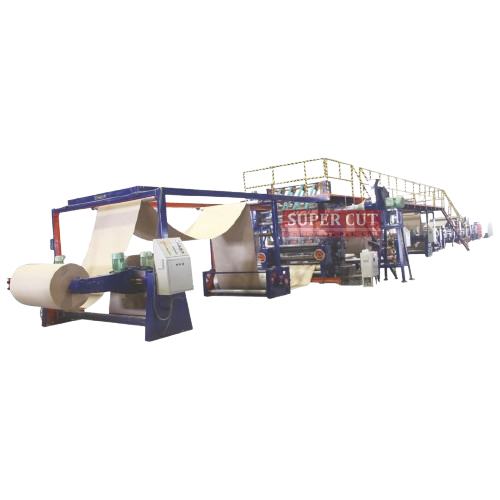

5 Ply Plant Production Line / Layout

In Stock

- Process Workflow:-The paper shall be transmitted from mill stand to single-roller for pre-heating and humidity adjusting, to single facer to further

heating, fluting and gluing to be single-corrugated sheet, then to over bridge through pulling for orderly transmitting, to multi-roller pre-heater for again heating, to pasting machine for gluing, to double facer for bottom paper combination to be corrugated sheet, to slitting machine and NC cut off for required sheet and lastly to stacking machine for stacking and outputting. - Available width 1400mm-length 2200mm and can be customized.

- Production speed-60m/min to 220m/min.

- Fluting type-A flute, B flute, C flute, E flute.

Description

Be the first to review “5 Ply Plant Production Line / Layout” Cancel reply

Video

Related Products

No related products found.

Reviews

There are no reviews yet.